The Process and Results of Dent Repair on a Ram Truck Using PDR at Excel Dent Removal

This past summer, our dent shop had the pleasure of working on a Ram truck that came in for extensive damage, including multiple door dings, a minor dent, and a broken taillamp that needed replacement.

Our team was dedicated to ensuring that every detail was addressed, and we collaborated closely with our customer to create a comprehensive repair plan that met their needs. Understanding the financial implications of automotive repairs, our customer made the wise decision to file a claim with their insurance company. Given that the costly repairs of an auto body shop for the damages would have exceeded $3,000, it was essential to clarify that these repairs would surpass their deductible, allowing them to avoid out-of-pocket expenses beyond what was necessary.

After the repairs were completed, we are thrilled to share the outstanding before-and-after results from the dent repair process. We used advanced techniques to restore the truck’s exterior to its original condition, carefully mitigating the impact of the dents while ensuring a flawless paint finish. In the images below, you can see the remarkable transformation that took place. We also want to take a moment to explain the steps we undertook during the repair process, which included assessing the damage, employing special tools for dent removal, and the need for proper calibration of electronics.

Our goal is always to provide exceptional service and results that our customers can rely on, and this Ram truck is a testament to that commitment.

Benefits of PDR for Your Truck

When it comes to maintaining the pristine appearance of your Ram truck, understanding the complexities of dent repair is essential. At Excel Dent Removal, we specialize in Paintless Dent Repair (PDR), a revolutionary technique that restores your vehicle’s body to its original condition without the need for sanding, body fillers, or repainting. PDR is particularly effective for fixing minor dents and dings caused by hail damage, shopping cart mishaps, or minor collisions.

At Excel Dent Removal of MN, our skilled technicians leverage their expertise in autobody dent repair to ensure that each vehicle is treated with precision and care. The benefits of PDR include a quicker turnaround time, reduced repair costs, and the maintenance of the vehicle’s factory finish, making it an ideal solution for both minor damage and cosmetic auto repairs. By choosing paintless dent removal, vehicle owners will have the peace of mind and can expect exceptional results that enhance the longevity and visual quality of their vehicles.

The PDR Process at Excel Dent Removal

Initial Assessment

The initial assessment is a crucial step in the PDR process. When our customer’s Ram truck arrived at Excel Dent Removal, we began by thoroughly examining the vehicle to identify the extent of the damages and the location of the dents. Various factors, such as the size, depth, and type of damage, are taken into consideration to determine the best approach for repair. We also made note of the damage and crack to the right taillamp.

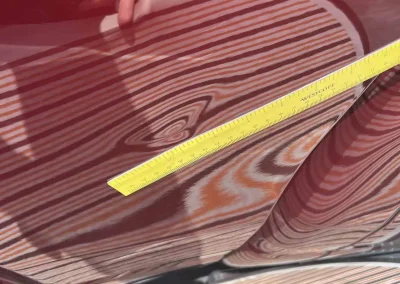

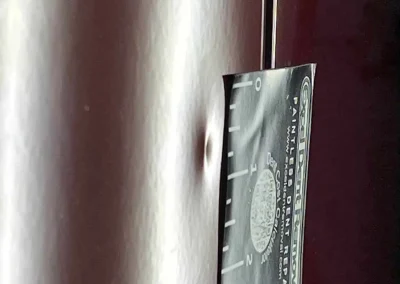

During this phase, we also discuss the truck’s history with the owner, capturing details about when and how the dents occurred. This dialogue helps our technicians understand the specific concerns of the owner and sets the stage for what can be achieved. Utilizing specialized lighting and reflection boards, we enhance the visibility over the dented areas, allowing for a thorough evaluation.

We will also explore whether they have received additional quotes from the auto dealership or other auto body repair shops. Additionally, we will inquire if they have filed a claim with their insurance provider or if they need assistance in submitting an accident damage claim.

The customer has shared that he obtained several estimates for replacing the taillight and repairing the dents on the adjacent panels, with quotes amounting to several thousand dollars. He mentioned that he was considering filing an insurance claim, as the estimated cost for just the taillight replacement, including parts and sensor recalibration, is approximately $2,000.

Our PDR technicians are trained to identify the type of metal and its characteristics, as cars are often constructed using various alloys that behave differently when manipulated. By taking all these critical aspects into account, we provide a realistic estimate for the repair time and costs involved, ensuring transparency from the beginning.

With this initial assessment completed, we prepared to move forward. Clients are given an understanding of what the repair will entail, including expected results. We will proceed to schedule the repair dates and order any necessary parts. If it is required to coordinate with the insurance company for approval of our estimate, we will initiate that process as we have experience working with all major insurance companies.

One of the top priorities at Excel Dent Removal is customer satisfaction, and our detailed preliminary review helps set realistic expectations.

Tools and Techniques Used

At Excel Dent Removal, we utilize state-of-the-art tools and techniques specifically designed for paintless dent repair (PDR). This method allows us to restore the vehicle’s body without compromising the factory finish, offering a cost-effective solution for our customers. Below, we outline some of the key tools and methodologies we employ during the dent repair process on Ram trucks.

Specialized PDR Rods and Hammers

Our technicians use a variety of specialized tools designed to reach intricate areas of the truck’s body panel. These rods are essential for applying strategic pressure on the backside of the panel to gradually massage the dent out without damaging the paint. Complementing the rods are unique hammers and tap downs that allow our technicians to finesse minor imperfections and achieve a smooth finish.

Heat Guns

To enhance the malleability of the metal, we apply heat using professional-grade heat guns and infrared lamps. This technique softens the metal material, making it easier to manipulate. The controlled heat application prevents any risk of paint cracking. By raising the temperature carefully, our technicians can work more effectively, ensuring optimal results.

PDR Lights

In the world of paintless dent repair (PDR), proper lighting is essential for achieving optimal results. LED PDR lights have revolutionized the way technicians assess and fix dents on a car’s surface. These specialized lights help highlight imperfections and ensure that every dent is accurately identified and addressed.

Repair Steps Explained

Driver’s Door Small Door Ding Repair

As soon as our customer dropped off their truck for repairs, we got right to work on addressing the damages. Our first step was to tackle the small door ding on the driver’s door. To ensure we had the best access for our paintless dent repair tool, we carefully removed the window belt molding. Then, with gentle and precise pushing, we worked to restore the door to its original condition.

Minor Dent Repair to Right Front Door

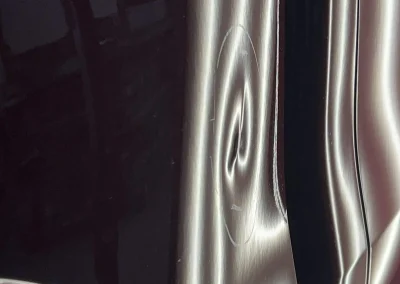

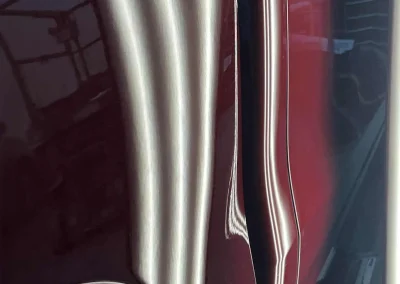

The next step in the repair process will focus on addressing the damage to the lower bodyline of the right front door. To begin this repair, it will be necessary to remove the inner door trim panel for better access.

Repairing this type of damage can be a bit more challenging, as it is often caused by another door edge impacting the panel. The result is a several-inch crease that has unfortunately caused some deep damage to the bodyline.

This dent repair process begins by using hot glue along with several PDR tabs to gently lift the dent. This technique is effective in reducing the amount of pushing required with a PDR rod, making the overall repair smoother and more efficient.

Then to ensure a successful repair, we used precise knockdown tapping and careful pushing to minimize any visible marks and preserve the integrity of the original paint.

Minor Accident Damage to Right Boxside

The next area I focused on was the larger damage to the right box side. A 4-inch shallow dent was left in the middle of the box side, just in front of the rear wheel well. To start the repair, we used cold glue along with a specially designed slide hammer to lift some of the dented area.

Next, I gently removed the inner plastic wheel liner to gain access behind the panel. This allowed me to use PDR (Paintless Dent Repair) tools to carefully push out the remaining dent until it was restored to its original shape.

Replacing The Broken Tail Light

The final task to complete on the truck was addressing the cracked taillamp. Although this repair was relatively straightforward, it turned out to be the most costly, with the replacement taillight priced at over $1400.

Additionally, since the taillight houses the blind spot monitor module, it required recalibration and a road test to ensure everything was functioning correctly.

Advantages of Choosing a Reputable PDR Service

When selecting a provider for dent removal, Excel Dent Removal of MN stands out as a leading choice for paintless dent repair. The team is equipped with advanced techniques and tools tailored specifically for effective dent repair on vehicles like the Ram Truck. Their expertise ensures that every dent is addressed with precision, preserving the integrity of the truck’s original paint finish and avoiding unnecessary bodywork. Customers can trust that the skilled technicians at Excel Dent Removal will handle their vehicle with care, ensuring high-quality results that meet the highest industry standards.

Moreover, Excel Dent Removal is committed to delivering exceptional customer service throughout the entire dent repair process. From the initial assessment to the final inspection, clients are kept informed and reassured about the work being performed. This transparency, combined with their extensive experience in dent removal, fosters a level of confidence that is crucial when entrusting someone with your vehicle. Choosing Excel Dent Removal for PDR not only guarantees a remarkable outcome for your truck but also an enjoyable and stress-free experience.

As more vehicle owners become aware of the advantages of PDR, it is evident that this method will continue to gain traction as a preferred choice for dent repair in the automotive industry. Excel Dent Removal’s commitment to quality service ensures that customers can trust their vehicles are in capable hands, making them a reliable option for those seeking dent repair solutions.

If you’re in need of expert dent repair services and are looking for cost-effective solutions, Excel Dent Removal in Blaine, MN is here to help!

Contact us today to begin the process of restoring your vehicle. We look forward to assisting you!

Customers Review

“Looking for paintless dent repair? Stop looking! Steve at Excel Dent Removal is the only place you need to consider.

Some of these reviews state he is “good.” He’s impeccable. Extremely friendly, knowledgeable and the entire process was so seamless. I had three dents removed, two of them pretty tricky and a broken tail light replaced and the truck looks brand new!

I cannot say enough about this place! Thank you so much, Steve!“